Greenhouse Irrigation

When planning the construction of a greenhouse on your property, one of the most important considerations to make is proper irrigation. While you could use a watering can for each plant, there are systems available that will make that job easier and supply your plants with an even disbursement of water, even without human intervention, making the development of your greenhouse far more calculated. While planning your greenhouse, you will need a water supply and a drain, so excessive water will not collect on the floor, causing a slipping hazard. Solar Innovations® implements two distinctive irrigation systems — Drip irrigation and Misting irrigation. To make the care of your plants less time consuming, a controller should be incorporated into your design.

Drip Irrigation

Benefits

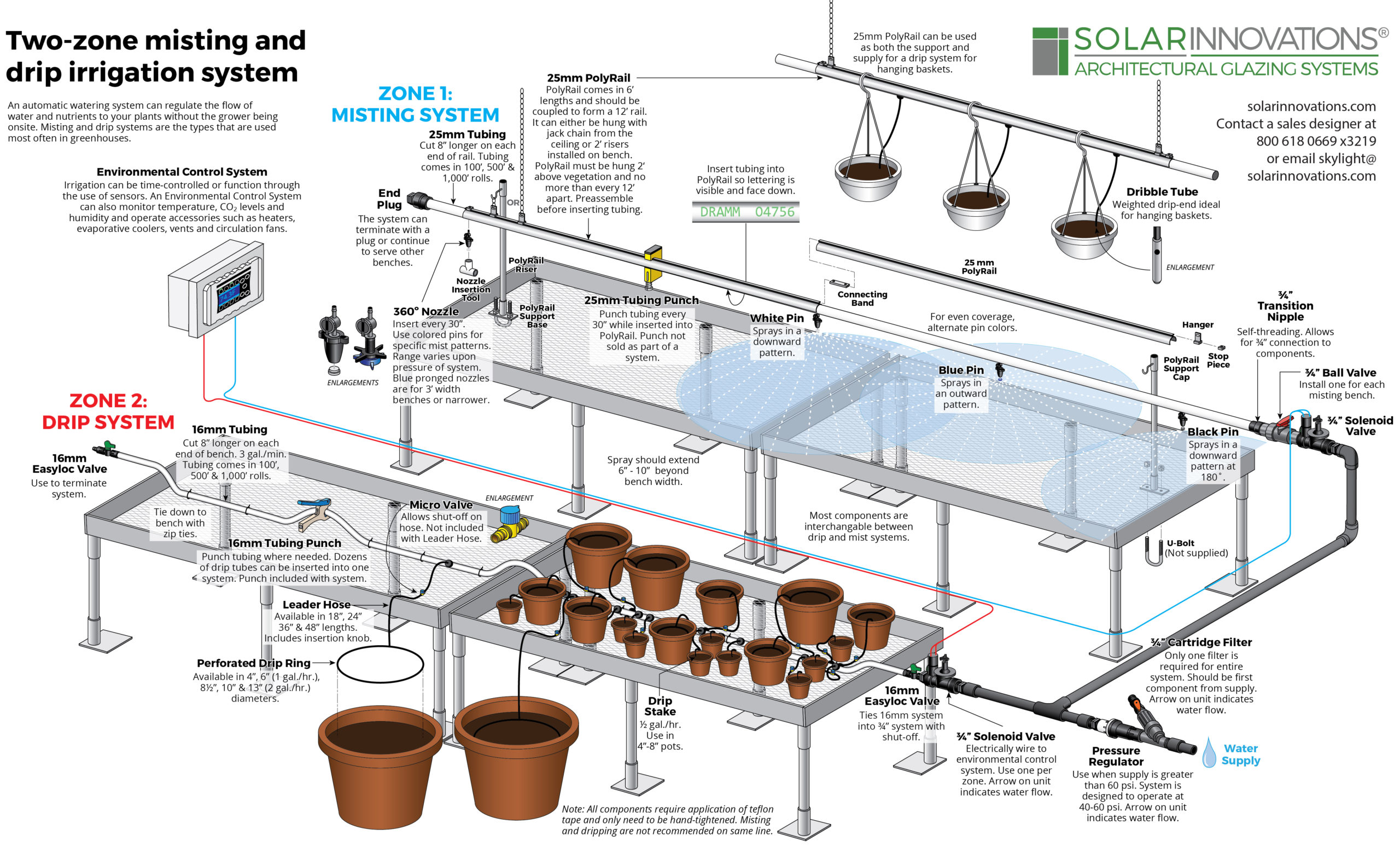

A drip irrigation system is designed to deliver small amounts of water over an extended period of time. Unlike a misting system, which sprays water over the entire plant in greater quantities and for shorter bursts, a drip system concentrates its irrigation delivery to the roots of the plant. This gradual hydration technique is ideal for delicate seedlings that may get damaged by the force of the spray from a misting system. This method also allows for even water distribution to all plants using the same components. Drip systems are not limited to seedlings. Some larger plant species thrive from the slow saturation method, and there are a variety of delivery systems that can accommodate pots of up to 16” in diameter. A hybrid misting and drip system can be setup to deliver alternating or simultaneous irrigation, zoned irrigation on separate benches and/or service hanging baskets. Both systems can be tied to an environmental control system for hands-free operation.

Setup

For all greenhouses, a water supply and drainage is required. The main line of the system should consist of either 1” or ¾” PVC or polyethylene tubing. Polyethylene tubing is compatible with twist-on fittings that allow for quick and easy installation and is the ideal material for this type of setup, as it self-seals around each insertion point. At the source of the water, an inline filter should be installed next to a manual shut-off valve. Drip systems typically deliver water at 1 – 4 gph. If the main line delivers water pressure greater than 50 psi, a pressure regulator should be installed to bring the pressure between 15 – 50 psi. For multiple benches or a multi-zone system, it is at this point in the line where a series of tee fittings should be installed. For each branch, a manual shut-off valve should be installed to maintain maximum control of water delivery. For an automated system, it is at this point where solenoids for each leg should be installed. Flexible hose, such as garden hose, should be used for rolling benches so the benches can move freely without disrupting irrigation.

Once the system reaches the bench, the tubing can be reduced to either 16mm or ¾” polyethylene tubing. This will serve as the main line for the length of the bench. An end cap, or shut-off valve, should be installed at the end of the line. Using a puncture tool, holes can be placed anywhere along the length of the main line. ¼” tubing with barbed pressure compensators is inserted into each hole and fed to each pot. Drip systems can utilize dribble rings or weighted dribble tubes. Dribble rings come in a variety of diameters and are ideal for equal water distribution in larger pots. Weighted dribble tubes concentrate irrigation to one location and work well with seedlings and hanging baskets. For optimal control, microvalves can be installed in each feeder tube.

A Drip Irrigation system can work independently or in tandem with a Misting Irrigation system. The system can also be be setup in zones, where water can be distributed to different areas within the same greenhouse at varying intervals of time. Thought it is possible to do this manually, it is recommended that a controller be used for consistent results. For rolling benches, it is recommended that flexible hose, much like a garden hose, be used for each bench, or between adjacently connected benches, to maximize mobility.

Misting Irrigation

Benefits

A misting irrigation system simulates rainfall, watering the entire plant gently and evenly. Unlike drip systems, which deliver small amounts of water over an extended period of time, a misting system delivers copious amounts of water and can quickly saturate plants. Because of this, they should be closely monitored or tied to an environmental control system, as the plants can quickly become overwatered. A misting system can serve a wide variety of plant sizes — limited only by the distance above the bench that the system is installed. Though most are mounted either 24 or 36 inches above the bench, these systems can be mounted as high as desired. A misting system can work in tandem with a drip system and be segmented into zones to deliver differing hydration levels to multiple benches within the same greenhouse.

Setup

When planning the construction of a greenhouse, a water supply and proper drainage is required.

The main line of the system should be constructed of either 1” or ¾” PVC or polyethylene tubing. Twist-on fittings can be used for polyethylene tubing, making for a quick and easy installation. At the water source, an inline filter should be installed first, followed by a manual shut-off valve. Misting systems are designed to operate between 15-70 psi. If the water pressure of the system is too high, a pressure regulator can be installed. For a multi-zone system, it is at this point that the system should be divided into multiple runs, each controlled by its own shut-off valve or solenoid for electronically controlled systems. For rolling benches, it is recommended that flexible hose, such as garden hose, be used for each bench, or between adjacently connected benches, to maximize mobility.

For each bench, or series of benches, the misting system can be installed two ways – bench-mounted or ceiling-hung. For a bench-mounted system, aluminum risers are attached to the bench(es) at 12-foot intervals, centered along the length of the bench(es). Polyethylene tubing is snapped into an aluminum pipe hanger and hung from the risers. The benefit of a bench-mounted system is that the misting system will travel with a rolling bench as it is repositioned. For a ceiling-hung system, jack chain is attached to the rafters of the greenhouse and lowered to the desired height. The tubing is then snapped into the pipe hanger and hung from the jack chain. At the end of the run, a plug must be installed. Using a hole punch, punch holes every 30 inches into the tubing. For optimal coverage, it is recommended to use an even amount of downward and outward spray pattern nozzles, inserted into the holes in an alternating pattern. Each barbed nozzle sprays in a 360° pattern with a flow rate of 0.48 gpm (1.8 lpm) and includes its own check valve, which prevents dripping.

Controllers

Automation can occur from as simple of a setup as placing an inexpensive timer with a valve on your water supply or as complex as a unit that operates heating and cooling systems, vents, fans and irrigation, such as an Environmental Control System.

Timers

Timers generally provide on/off functionality to watering systems. The simplest models can be operated with a 9V battery. They can be tied directly into a hose line, acting both as the timer and the valve, though this type of configuration is usually reserved for one irrigation line. For multiple lines, a hard-wired system tied to inline low-voltage solenoids should be used. Timers can have multiple programming cycles and, depending on the model, control more than one device. While a great choice for smaller greenhouses without many devices, timers are limited. For more complex operation, an Environmental Control System should be installed.

Environmental Control Systems

Environmental Control Systems are computers that gather information from inputs, such as weather stations, temperature sensors or humidity sensors and send out commands to outputs, such as valves, heaters, coolers, fans, vents and grow lights. Programs can also be set manually, and independently, for each output. For installations that require inputs and/or multiple outputs, Solar Innovations uses environmental controllers from Link4 Corp. These systems offer up to 10 inputs and 32 outputs, via expansion modules, and can even be controlled over Wi-Fi with a smart phone. They offer a ‘set it and forget it’ operation, controlling hydration levels, temperature, fresh air venting and circulation, as well as light emission. Different zones can be setup within the same greenhouse to give the grower total control of the environment for each individual area of plants. Data can also be tracked and logged into a spreadsheet. As these systems are quite sophisticated, they should only be installed by professionals, to ensure proper operation.

The setup of a greenhouse can be a daunting task. For each component (i.e. heaters, cooling systems, fans, lights vents) that is incorporated, the complexity of the project increases. Solar Innovations® Sales Designers are available to guide you in making the right choice, based on how simple, or complex the needs are in your greenhouse. For more information on greenhouses, greenhouse accessories, or any other Solar Innovations® products, please contact Solar Innovations® directly at [email protected] or call 800 618 0669.